The global leader in the design and manufacture of skimmers and large diameter floating suction lines for use worldwide.

As the global leader in the design and manufacture of floating suction lines and skimmers, and with more than 700 in service throughout the world, Matrix Applied Technologies’ Floating Suction and Skimmer systems lead the industry in proven design and quality.

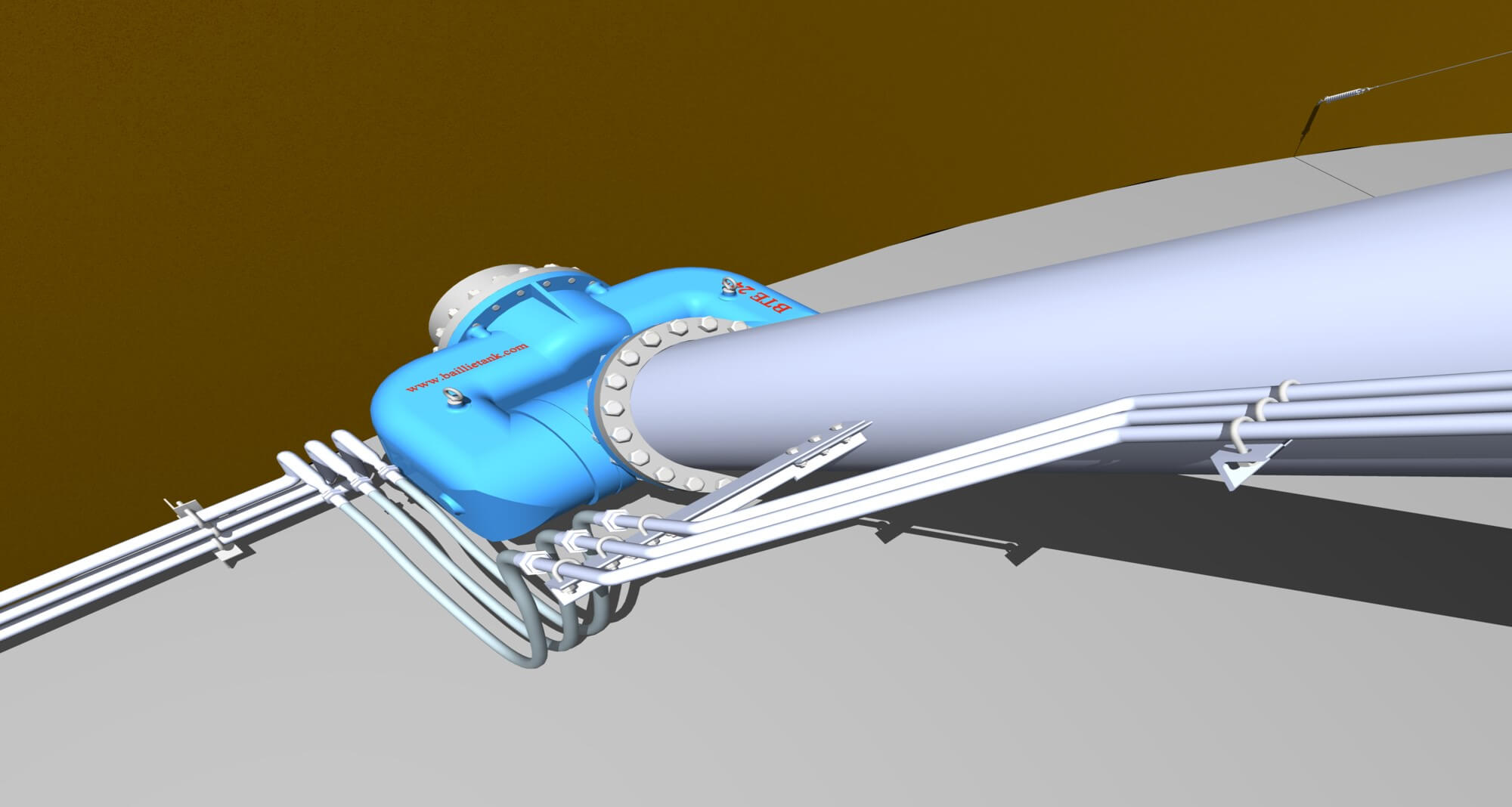

Suction lines and skimmers can be custom-designed to meet any tank configuration. Lines are either installed in fixed roof tanks or can be located below internal or external floating roofs.

Suction lines are commonly used for aviation Jet A-1 and Avgas tanks. Suction lines can be used in power plants, crude oil collection tanks or anywhere the quality of the product to exit the tank is an issue.

We can custom design floating suction lines and skimmers for various tank configurations. Lines are either installed in fixed roof tanks or can be located below internal or external floating roofs.

There are 2 main suction line types:

Both are available in line diameters 3 inches to 36 inches with larger diameters on application.

Designed to provide a visual indication that the suction line is operating properly, our level indicator consists of a cable connected to the suction line. The cable is connected to a weight running up and down guide rods on the outside of the tank shell and, in addition to providing visual indication that the suction line is operating correctly, also indicates the suction line’s position. A level indicator is imperative when the suction line operates beneath a floating roof.

Sample lines can be provided on the main suction arm for fuel sampling. Matrix Applied Technologies can provide ¾ or 1 inch diameter sample lines. Typically, sample points are located at the center of lower third, middle third and upper third of the tank liquid level.

Roller type floating suction lines are fitted with rollers that run along the underside of the steel floating roof. No special track is required and the roller can negotiate plate overlaps. The same suction line can operate beneath an aluminium or stainless steel Internal Floating Roof (IFR); however, in this situation, a track must be added beneath the IFR to accommodate the roller. As a premier IFR manufacturer, Matrix Applied Technologies can design an appropriate suction line track and provide extra buoyancy for aluminium or stainless steel IFRs when necessary.

When tank height is greater than tank diameter, a single arm suction line will not reach maximum liquid level height. In this case, a two-arm or articulated suction line is required. A similar articulated configuration can be used for skimmer lines.

These are designed to skim off a layer of hydrocarbon liquid floating on top of water. Essentially, a skimmer is designed to remove the top layer of a two-phase liquid stored in a tank. Line sizes are usually 3 or 4 inches, although Matrix Applied Technologies can manufacture larger sizes. Pontoons are designed to float on their centerline at the lowest S.G. tank product. The skimmer plate is located an adjustable distance below this.

Move to a higher standard. No matter where you are in the world, the industry’s premier products are just an email and a data sheet away. Or contact us for more info by filling out the form below.